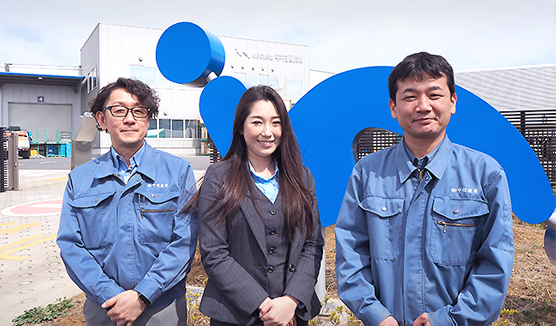

Surrounded by flourish nature, Asagiri Maple Farm Co., Ltd. is located in grand field on Asagiri plateau, a foot of mountain Fuji. Company raises 450 milk cows and provide quality milk worldwide. Since its opening in 2006, the company is working hard to expand their business as well as establish organizational structure with the aim of expanding the size of the farm to the biggest in Japan. The employees mentioned that they felt the positive changes have made to the company due to the introduction of LINE WORKS. We interviewed a leader of the farm Mr. Maruyama, assistant leader Mr. Okada, and feedstuff manager Ms. Hasegawa about the detailed usage experience of LINE WORKS.

Tell us about your company and individual roles

Mr. Maruyama:

Our company raise milk cow and deliver 13 to 15 tons of milk daily. Myself, as a leader of the farm, I am taking leading roles in financial and production management.

Mr. Okada:

I am in charge of overall management of the farm, including taking care of the calves and cows, as well as the employees working on site.

Ms. Hasegawa:

I am in charge of managing feedstuffs for milk cows.

What were the issues before the introduction of LINE WORKS?

Mr. Maruyama:

Since the average age of the employees is about 25-26, which is comparatively younger generation, we previously used LINE as a company communication tool. What was the most problematic at that time was sending the wrong messages. In the past, because we were using the LINE for both private and business purpose, there was problem like sending the message to the colleagues, instead of sending it to the friends. It was risky and unstable in security perspective since we often share confidential information through messenger.

Also, in order to notify the symptom of the diseased milk cow in detail as well as to share professional information about the machine and facilities, we often share photos and videos through LINE. However, what we found problematic with LINE was that it was impossible to archive those attachments. For this reason, we hoped to use the business version of LINE if launched.

What was the decisive reason that drove you to turn to LINE WORKS?

Mr. Maruyama:

Our company is planning to expand the business, and in the same sense, we are planning to increase the number of employees up to 100 near in the future. To build an organization and make improvements to the communication tool, we have been thinking that an IT tool should be introduced to our company.

While searching for a business communication tool that is similar to LINE, we found LINE WORKS on the internet. Because LINE WORKS enables us to manage all the employees based on their positions, we believed that this would help us constructing organization. Also, as a ‘business version of LINE’, it sounded interesting to us. Those who are working at the farm are not all IT intelligent, and therefore, maybe a few employees who are having hard time memorizing the usage of the new tool. If it were LINE WORKS, however, we believed that employees soon be able to get accustomed to the tool due to its similarities of LINE.

How was the introduction of LINE WORKS?

Ms. Hasegawa:

Honestly, I was a bit nervous about having another application since I am not good at using machines and internet. But, as I start to use LINE WORKS, I realized that it was easy-to-use. Also, it was not having group chatting rooms inside LINE, but having them inside the LINE WORKS. This enabled us to share information much easier. Because we are using two different applications, it was good to have different notifications, since it allows us to find out whether the message is for private or business purpose.

How was the introduction of LINE WORKS?

Mr. Maruyama:

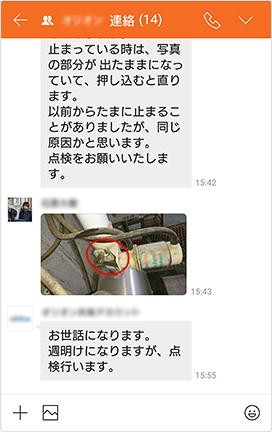

Our company encourages not only the employees but also mechanics and vets to make LINE WORKS accounts. If one of our machines is broken, we can directly send messages to the chatting room, in which mechanics as well as related people are also participating. This way, everyone can figure out the issue immediately, and does not forget to order pieces for repair. In addition, as all the employees share both symptoms and medical record of diseased cow through LINE WORKS, even with those who were not at the office could respond promptly to such issue. This has also contributed to maintain the health of the cow.

Mr. Okada:

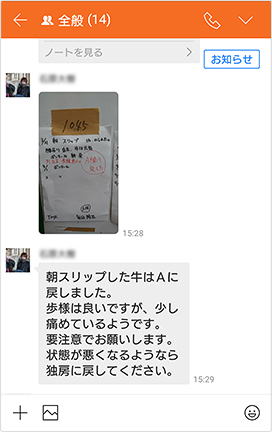

We share information about milk cows’ childbirth as well as daily issues through messenger. We also upload meeting logs to the board. Previously, if we had a meeting with specific employees or project members, we used to print out the computer-written meeting logs and told the employees to write names on the paper if they read the log. With LINE WORKS board, however, it allows us to read the meeting log whenever we want and we can also find out whether every employee has read the log or not.

Ms. Hasegawa:

I am sharing information with all the employees with regards to feeding the milk cows. We decide the amount of the feed to give to the milk cow next day, based on how much did the milk cows eat their feeds on the day. And bad conditioned feed is one of the reasons to consider. We constantly share information in order to track what are the ingredients are included in the feed and act accordingly to it.

What are the effects after the introduction of LINE WORKS?

After the introduction of LINE WORKS, various changes are made to our company, and it helped us with efficient working as well as human resource management.

Because it is a tool that we use on a daily basis, we can follow the rules regularly

In order to keep the resting place for cows as clean as possible, we put sawdust on the cow bed. Before using LINE WORKS, random employees, who thought about changing the sawdust did the cleaning once in two years. But, after the introduction, we started to write the cleaning schedule on the Calendar to do the cleaning once every three months. As a result, we could sustain the beddings for the cows clean and ultimately, we could also reduce the possibilities of cows getting diseases.

Most importantly, we could follow the rules regularly. There are various calendar tools, but what we think the most important is that we get notifications on the schedules through the tool that we use on daily basis. Since the notifications are sent through the tool that is mandatory to use, we cannot miss the alarm and therefore, we can follow the rules.

We can save unnecessary time for travel since we are able to check about 200 manuals using smartphone

We have about 200 manuals on the works needed in the farm, such as milking and coping method for cow disease. Before the introduction, all the manuals are saved on the computers located inside the office. For this reason, we had to go to the office to check the manual. After introduction, however, it became much comfortable for us since we can save all the manuals at the drive and download them on my smartphone whenever wanted.

‘Listening to opinion’ has become our new culture. And, with this, we could successfully finish our cleaning project!

We had a problem keeping the farm clean and neat for a long time. After the introduction of LINE WORKS, however, we came up with a goal to make a successful story of making our farm clean. We immediately started an organization and cleaning project using the Note feature. The employees first visited and inspected the clean farms as an example, and we shared reports with photos attached to the Note in order to decide which farm to take it as an example. Furthermore, we conducted a survey asking questions like what are the problems at our farm and which part of our farm should be cleaned. Two months later, we could successfully finish our cleaning project and keep our farm clean. In fact, the project was meant to be started 3 years ago, but it did not go well at the time. Because we could gather up all the employees’ ideas and thoughts in one place, there was no detailed idea made regarding the project. With Note and Survey feature, we could share thoughts and ideas and listen to others as well. We believe this motivated all the employees in our company.

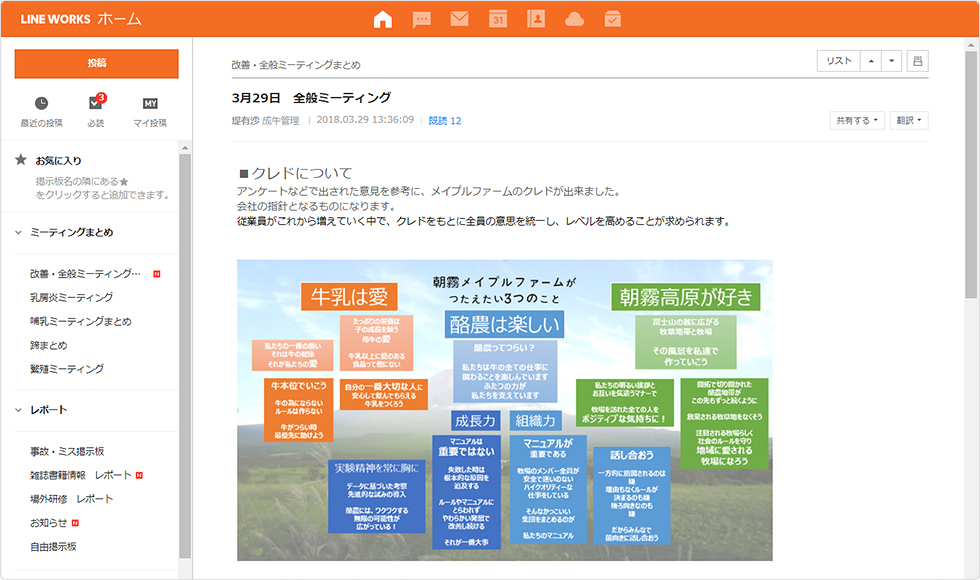

We were able to create a business credo that reflects the will of the employees

As the number of employees increase, we were constantly thinking about documenting the company’s business credo as well as value of the farm with the aim of keeping our corporate climate strong and tight. To do this, all the employees gathered through the LINE WORKS Survey feature. All the employees answered what they thought about the social significance and responsibility of Asagiri Maple Farm. Before the introduction of LINE WORKS, employee’ comments were received via written memo or verbal communication. Also, we had to fill the excel form to accumulate the survey result. The overall process was burdening for all of us. We also had difficulty communicating opinion with others. LINE WORKS survey, however, was very easy to use. Because collecting and sharing opinion became so easy, the feature has enabled us to create our business credo together with our employees.

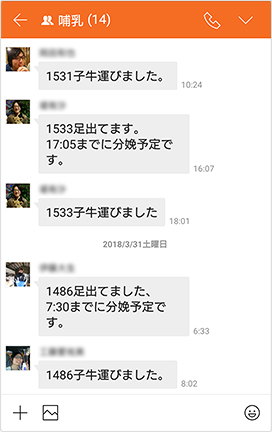

By sharing and checking up calves’ birth in real time, the calves’ fatal death rate has been reduced from 10% to 5%.

Our company had a mission to reduce the calves’ fatal death rate since we had a bit higher rate when compared with other farms. For this reason, we started to use LINE WORKS Messenger feature to increase the frequency of observing cows and share the situation in real-time. As all the employees are able to acknowledge about the condition of the cows, we could be more cautious and pay more attention to those cows. About 6 months after the introducing LINE WORKS, we could reduce the fatal death rate from 10% to 5%.

Mr. Maruyama:

As information sharing became smoother, we can process all the projects harmoniously. In corporate perspective, growth rate as well as group gathering force have also increased. Moreover, as we can now manage our work, efficiency of production management has improved, which is positive change made to our company.

※ All details, affiliations, and positions specified were gathered at the time of interview.